Optimizing Highrise Construction

This project aimed to install a capillary break with 5/8- aggregate to prepare a slab for a high-rise building.

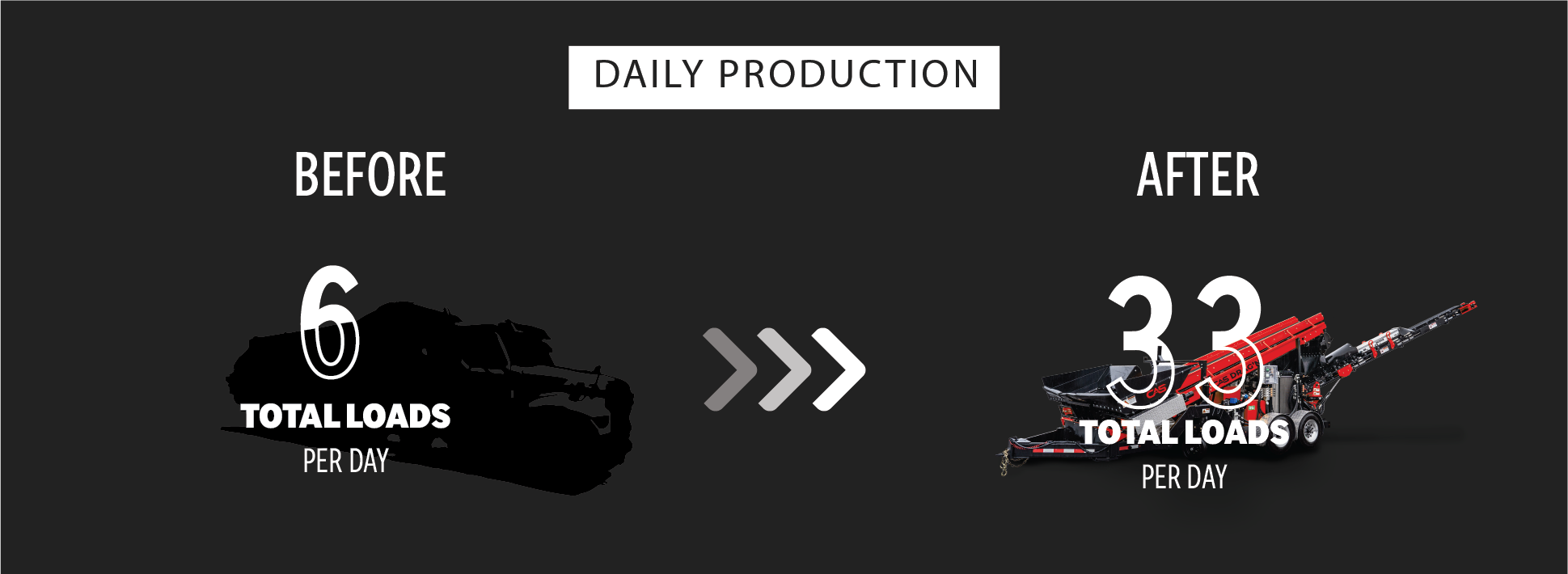

The General Contractor (GC) initially employed two slinger trucks to execute the work. However, their maximum daily production was limited to six loads each day per truck, causing the project to fall behind schedule.

Challenges Faced:

- Slow Production: The limited production capacity of the two slinger trucks led to a slow progress rate.

- Schedule Delays: The project was already behind schedule, and the slow production further exacerbated the situation.

- Distance to Pit: The source of the required material (5/8 chips) was located approximately 30-45 minutes away from the construction site, adding to transportation time and costs.

Solution:

Facing these challenges, the GC reached out to Mickelo, a company known for its innovative construction solutions. Mickelo proposed the use of their specialized equipment, the CAS DRAG’N, to enhance production rates and expedite the project. Upon the introduction of Mickelo’s DRAG’N to the project, the results were nothing short of remarkable:

- Production skyrocketed to 30 loads in one day.

- Five dump trucks were effectively making turns, ensuring a continuous flow of material.

- The following day, production reached 33 loads with six dump trucks making turns.

- Despite the pit being located 30-45 minutes away from the site, Mickelo’s equipment allowed for efficient and rapid material transportation.

Outcome:

By collaborating with Mickelo and adopting the DRAG’N solution, the General Contractor achieved the following outcomes:

- Significantly Improved Production: Production rates increased sixfold, enabling the completion of a substantial amount of work within a short timeframe.

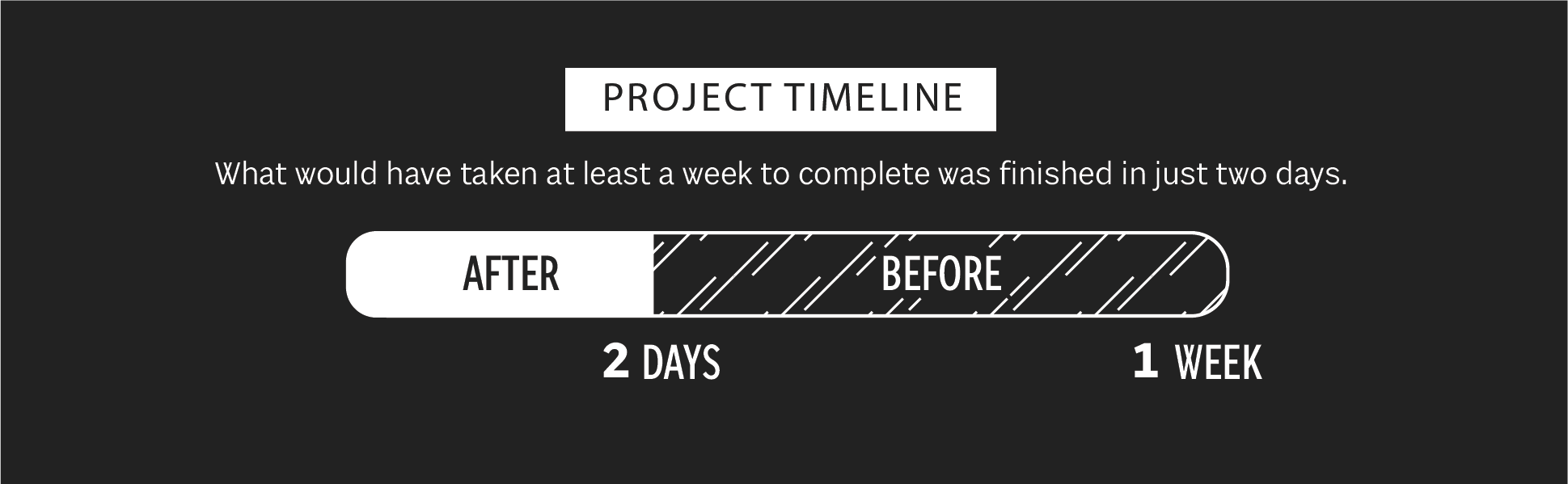

- Timely Project Phase Completion: What would have taken at least a week to complete was finished in just two days.

- Schedule Adherence: The project was brought back on track, mitigating the delays and potential cost overruns.

- Cost Savings: The efficiency gains resulted in reduced labor and equipment costs.

Conclusion:

The case study exemplifies the importance of innovative construction solutions in meeting the demands of modern high-rise construction projects. Mickelo’s DRAG’N not only boosted production but also ensured timely project phase completion, offering substantial cost savings and enhancing the overall efficiency of the construction process. This success story serves as a testament to the significance of adopting cutting-edge technology in the construction industry.